Injection Molding Factory Layout

The whole process from product drawing to mold makingand then to injection molding. Design world 151112 views.

For The Selection Of Plastic Injection Mold Factory To Fulfill

For The Selection Of Plastic Injection Mold Factory To Fulfill

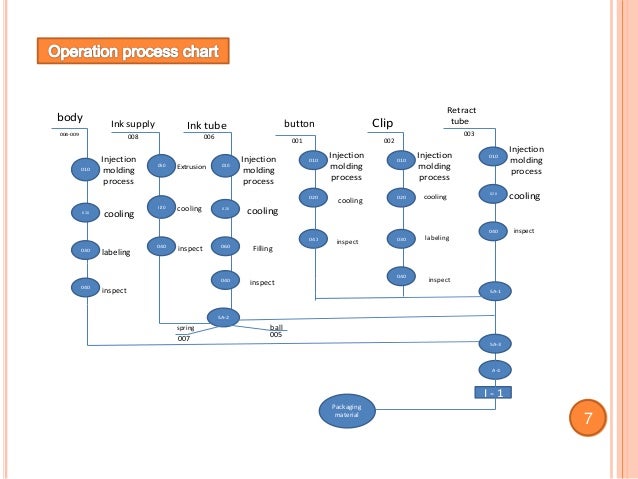

In this example specialized product filling flows into general purpose inspection and packing.

Injection molding factory layout. Machine layout can influence how many machines can fit in a designated area but it also can determine the number of operators required to attend to the automated injection molding machines. 6 sets of cnc precision 0005mm 14 sets of mirror edm 8 sets of slow wire cut 12 sets injection molding machines range from 60 ton to 800 ton 1 set of 2d. The following is an edited excerpt from the business of injection molding by clare goldsberry.

The design engineers checklist for injection molding. Depending on the layout an operator may have the ability to tend to two three or even four machines. The manufacturing plant currently has 8 injection molding machines from 15t to 380t and we have a 750t on its way.

New injection molding factory layout we are currently designing our new factory layout we currently have a team of 12 people which we expect to grow to 20 people within the next 2 years. It is most typically used in mass production processes where the same part is being created thousands or even millions of times in succession. The book is the first title in the imm book club injection molding management series published in 1998 by imm and abby communications.

Plant admin and operation offices building amenities plastics injection molding a 15 from dedicated cells into modular packaging lines a typical layout. Welcome to orangered the 1 sourcing company and founder of the dpi development production import and ios interactively on site methods. The principal advantage of injection molding is the ability to scale production en masse.

Injection molding is a manufacturing process for producing parts in large volume. Step by step at the factory field notes. Molders say the design pros are aware that plant design is a lot more than lining up molding machines with optimal spacing between them.

While much of the focus here is on a custom injection molding operation many of the points about plant layout machinery and equipment required and staffing apply to captive molding operations as well. Our equipment includes but not limited to. It is more like conducting an orchestra of material handling automation energy consumption utilities ergonomics and architecture as it plays the value chain symphony.

Get access to factories producing for multi billion. Resin selection process choices and design specs. Why use injection molding.

Facility we are a fully equipped injection mold factory we have completely in house mold making capacity proceed from mold design to cnc edm wire cut polish mold fitting and mold testing. This article provide a handy list of considerations when searching out the.

Injection Molding Maximizing Data Acquisition And Wireless

Injection Molding Maximizing Data Acquisition And Wireless

Manufacturing Cell Layout Of The Factory Download Scientific

Manufacturing Cell Layout Of The Factory Download Scientific

Plastics Injection Molding Air Powered Double Diaphragm Pumps

Plastics Injection Molding Air Powered Double Diaphragm Pumps

Plastic Molding Service Custom Plastic Fabrication China Plastic

Smartbrush Fake Pictures Unico Fakebrush

Smartbrush Fake Pictures Unico Fakebrush

Plant Layout Design And Expansion The Best Looking Part Of A

Plant Layout Design And Expansion The Best Looking Part Of A

Injection Molding At Npe2018 A Showplace For The Smart Factory

Injection Molding At Npe2018 A Showplace For The Smart Factory

1 75 Mini Plastic Scale Model Figures Injection Mold For Scale

1 75 Mini Plastic Scale Model Figures Injection Mold For Scale

Injection Molding Machines And Auxiliaries Hirate America We

Injection Molding Machines And Auxiliaries Hirate America We

Are You Ready To Design In Three Dimensions Plasticstoday

Are You Ready To Design In Three Dimensions Plasticstoday

Chinese Injection Molding Company

Injection Mold Design Factory Custom Made Product Manufacturing

Injection Mold Design Factory Custom Made Product Manufacturing

New Injection Molding Factory Layout

Injection Molding Machine Operation Instruction And Good Habit

Injection Molding Machine Operation Instruction And Good Habit

Plastic Injection Molding Machine Plastic Molding Machine Plastic

Plastic Injection Molding Machine Plastic Molding Machine Plastic

Plant Layout Air Powered Double Diaphragm Pumps

Plant Layout Air Powered Double Diaphragm Pumps

Injection Molding Factory Youtube

Injection Molding Factory Youtube

Sunlumo Technology Gmbh Investors

Sunlumo Technology Gmbh Investors

0 Response to "Injection Molding Factory Layout"

Post a Comment