Sheet Metal Process Ppt

Sheet metal characteristics elongation the capability of the sheet metal to stretch without necking and failure. Steel deep drawing service sheet metal forming sheet metal deep drawing is the process of deforming steel deep drawing parts a sheet metal material into a cylindrical or box shaped part by a stamping pulling ring or metal mold process the deep drawing is usually carried out on the anti wrinkle pressure plate of the.

Defects In Sheet Metal Drawing Me Mechanical

Defects In Sheet Metal Drawing Me Mechanical

Ppt on sheet metal operation slideshare uses cookies to improve functionality and performance and to provide you with relevant advertising.

Sheet metal process ppt. Typically sheets of metal are sold as flat rectangular sheets of standard size. If you continue browsing the site you agree to the use of cookies on this website. This field is the basis of the calculation of the deformations stresses and internal forces necessary for the search of the stamped blanks equilibrium.

The results of a simex calculation are the shape of the initial blank enabling to. Yield point elongation lueders bands on low carbon steels and al mg alloys. The sheet metal blank is bent between a vshaped punch and die.

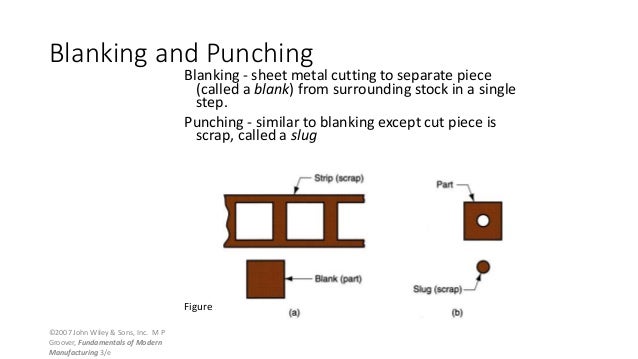

Small flexforming tool made by additive manufacturing. Therefore the first step in any sheet metal process is to cut the correct shape and sized blankfrom larger sheet. Hydro forming cheap tooling no net thinning slow high formability.

Two common bending methods are. Bending is a metal forming process in which a force is applied to a piece of sheet metal causing it to bend at an angle and form the desired shape. Luders bands can be eliminated by cold rolling the thickness by 05 15.

Scribd is the worlds largest social reading and publishing site. Sheet metal cutting forming processes general the raw material for sheet metal manufacturing processes is the output of the rolling process. It is one of the fundamental forms used in metalworking and can be cut.

Flanging is a process of bending the edges of sheet metals to 90 o shrink flanging subjected to compressive hoop stress. Stretch forming very cheap tooling net thinning slow low formability sheet metal up to 15mx9m loading pre stretching wrapping release. V bending edge bending v bending.

Sheet metal formingppt free download as powerpoint presentation ppt pdf file pdf text file txt or view presentation slides online. Sheet metal working introduction sheet metal is simply metal formed into thin and flat pieces. The periphery if the sheet metal is bent into the cavity of a die fig 1624 a bead forming with a single die b bead forming with two diesin a press brake flanging.

During the sheet metal forming process a displacement field is associated to the nodes.

Different Sheet Metal Operations With Diagrams Guide By Tips

Different Sheet Metal Operations With Diagrams Guide By Tips

Sheet Metal Forming Processes And Equipment Machinemfg Com

Sheet Metal Forming Processes And Equipment Machinemfg Com

Quality Management Information In Automotive Stamping Process

Ppt Sheet Metal Fabrication Know Facts About This Powerpoint

Ppt Sheet Metal Fabrication Know Facts About This Powerpoint

What Is The Difference Between Coining And Embossing Sheet Metal

What Is The Difference Between Coining And Embossing Sheet Metal

Cold Working Processes Total Materia Article

Cold Working Processes Total Materia Article

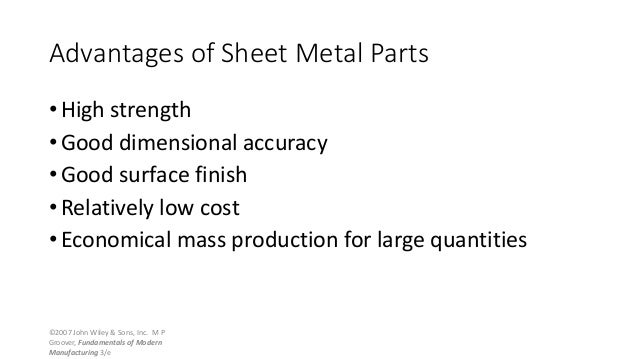

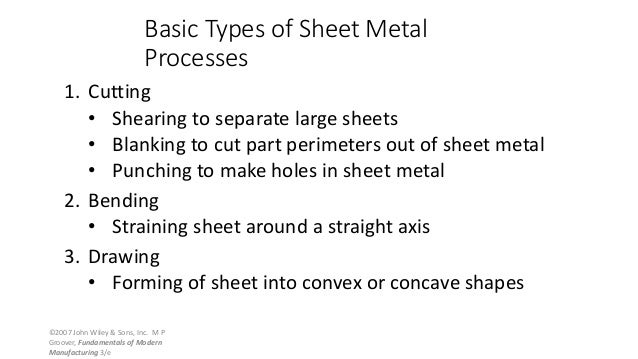

Ppt Sheet Metal Forming Processes Powerpoint Presentation Free

Ppt Sheet Metal Forming Processes Powerpoint Presentation Free

Automatic Design Of Sheet Metal Forming Processes By Un Forming

Automatic Design Of Sheet Metal Forming Processes By Un Forming

Lancing Sheet Metal Operations

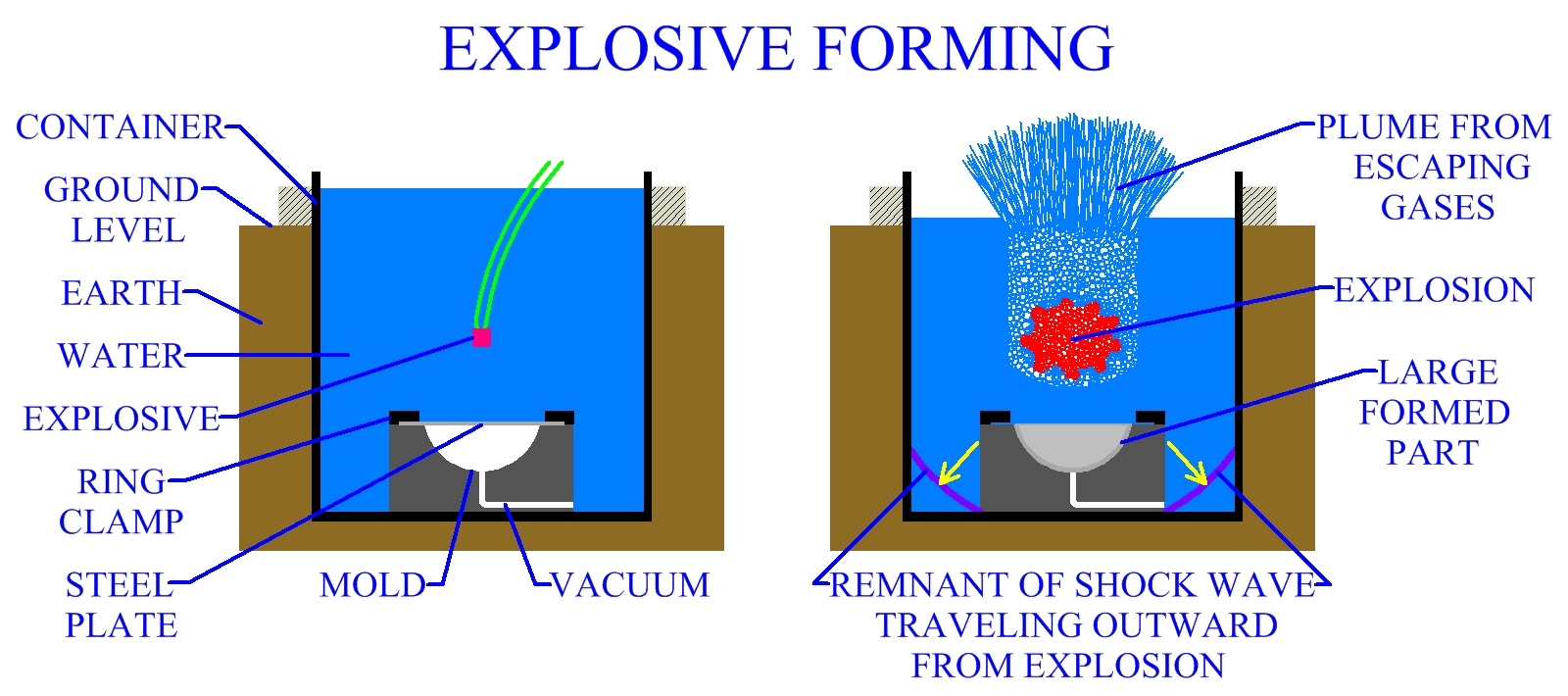

High Energy Rate Forming Of Sheet Metal

High Energy Rate Forming Of Sheet Metal

Prediction Of Formation Force During Single Point Incremental

Die Science The Process Of Fineblanking

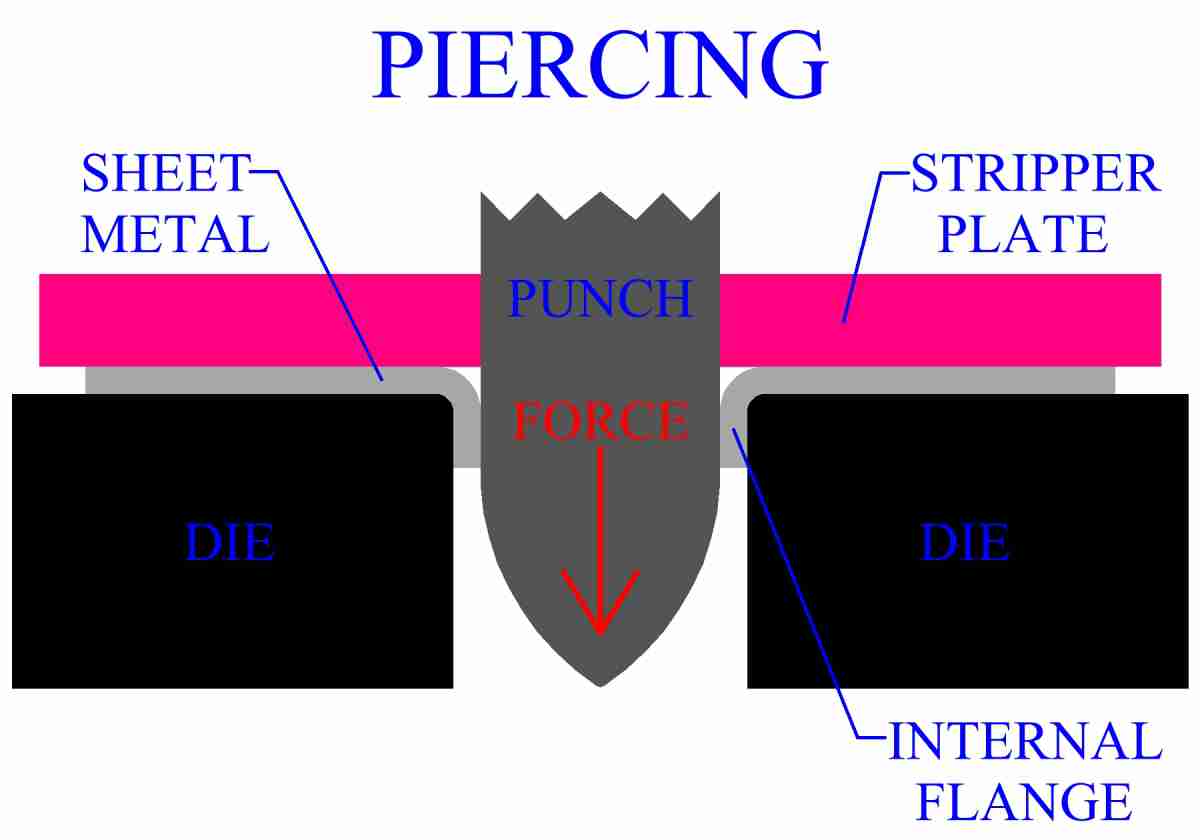

Difference Between Blanking Punching Piercing In Sheet Metal

Difference Between Blanking Punching Piercing In Sheet Metal

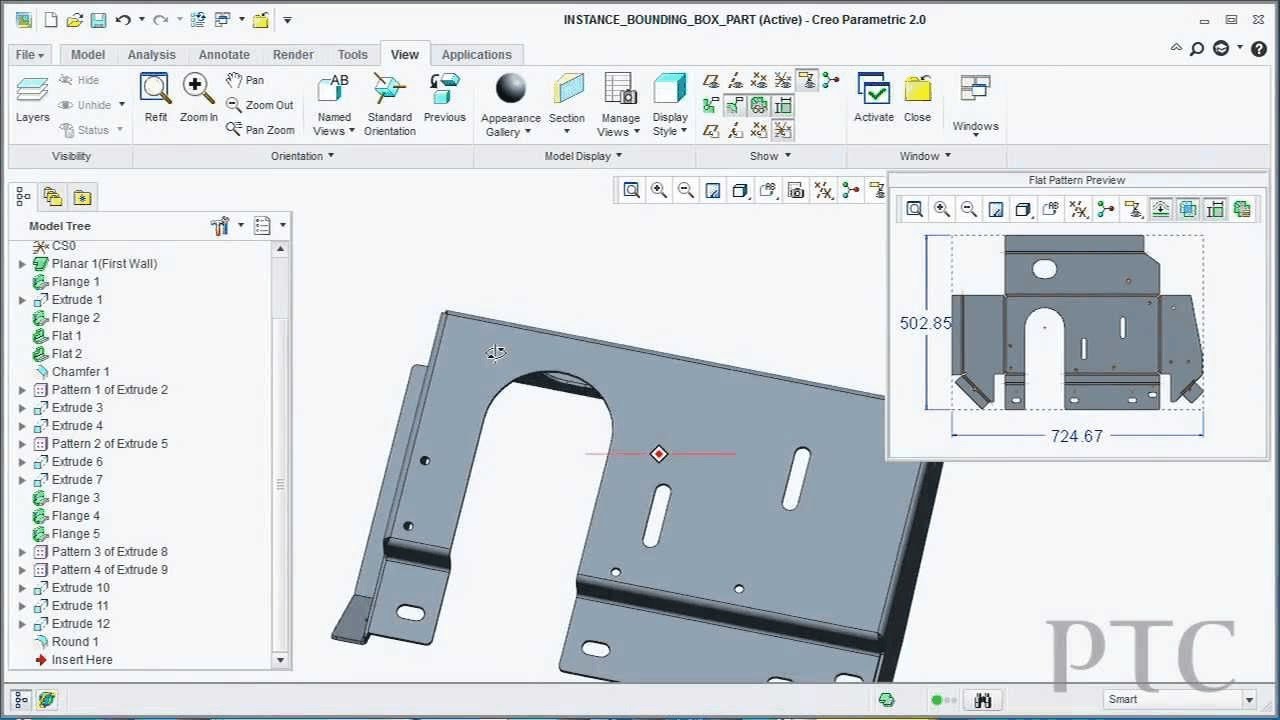

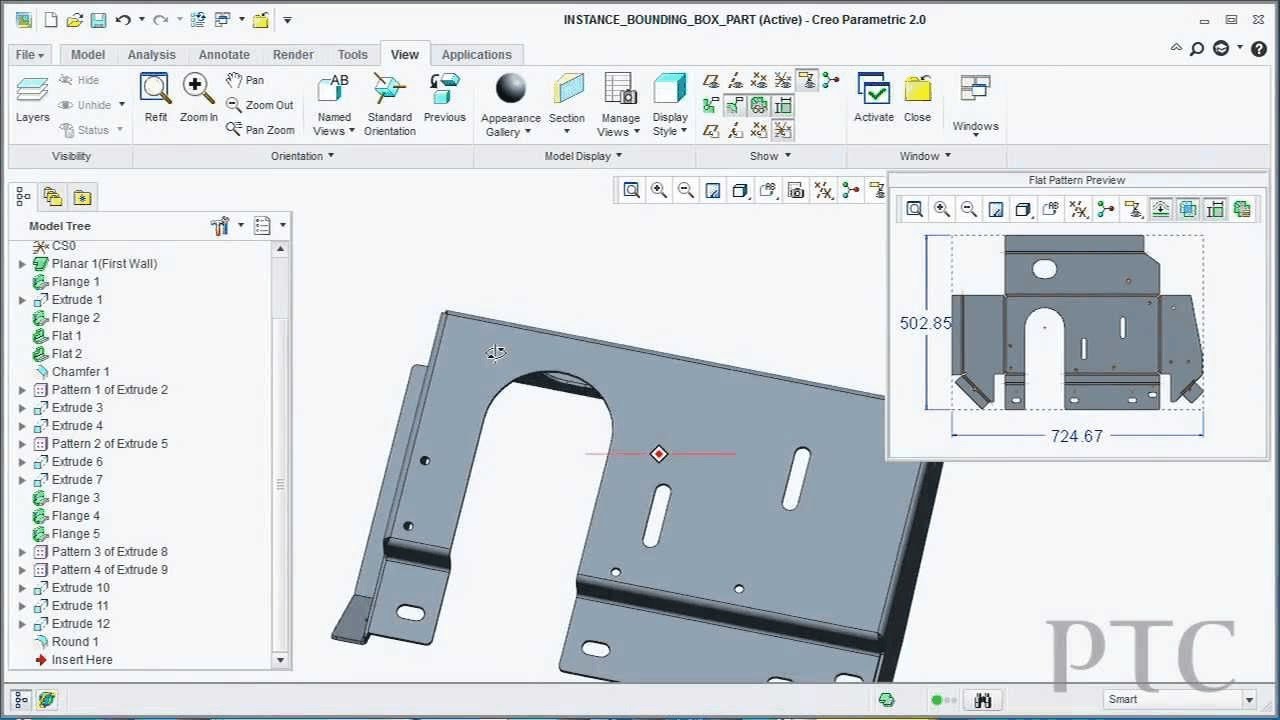

Creo 2 0 New Sheet Metal Capabilities For Creo Parametric Ptc

Creo 2 0 New Sheet Metal Capabilities For Creo Parametric Ptc

A Review On Forming Techniques For Manufacturing Lightweight

A Review On Forming Techniques For Manufacturing Lightweight

Difference Between Blanking Punching Piercing In Sheet Metal

Characterizing Influence Parameters In Pulsed Phase Thermography

Characterizing Influence Parameters In Pulsed Phase Thermography

Manufacturing Process Steel Sheets Products Nippon Steel

Manufacturing Process Steel Sheets Products Nippon Steel

0 Response to "Sheet Metal Process Ppt"

Post a Comment